AUTOMOTIVE

ENGINE DEEPHOLE DRILLING

There are many automotive parts manufacturers that trust Cougar to ensure their production stays on schedule and their parts are in spec. Custom tools are not easy to manufacture, especially when they are over a foot long! Below is one of our success stories in productivity!

Application:

Engine Block Deephole Drilling

Workpiece Material:

Aluminum

Machining Objective:

Drill Ø18mm hole full-depth approximately 330mm deep.

Description:

Cougar was approached by an automotive parts company and was challenged to develop a tool that would drill full depth and still maintain true position requirements. Our craftsmen were confident we could make a better tool than what they had been using.

Our Solution/Results:

Cougar designed & developed a drill using a proprietary polishing technique & point geometry to provide a superior drill that was able to achieve the customer's desired results. Our designed tool saved the customer 2.5 minutes of cycle time per part and greatly increased their throughput.

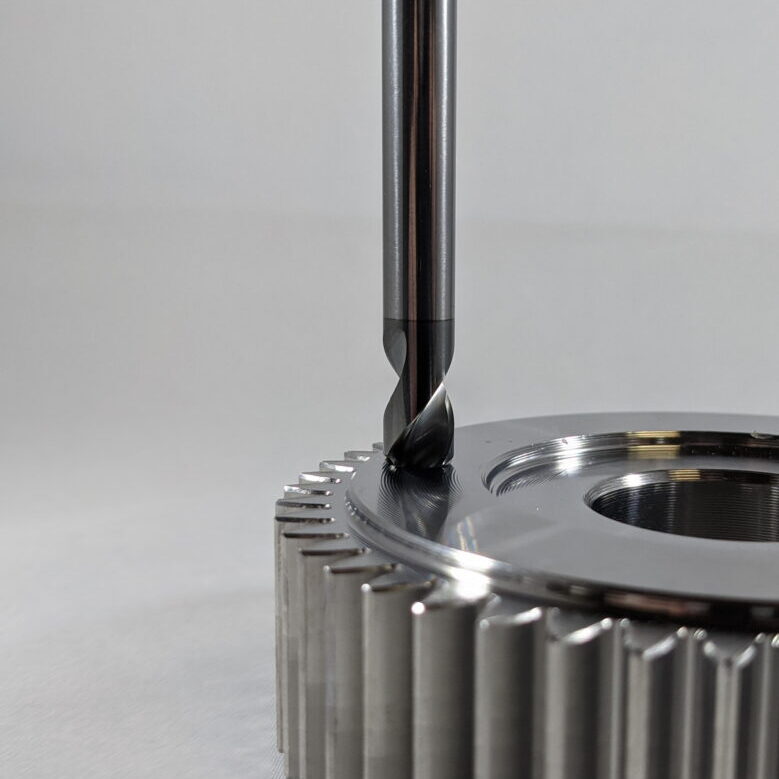

TAP DRILLING GEAR

Productivity is crucial to plant output. Reducing tool spend improves your operational bottom line, which provides you more flexibility to focus on other problem areas. Cougar has a long history of solving customer production problems with our tools, with some of our best success coming from combining operations into a single tool.

Application:

Gear Tap Drill & Chamfer

Workpiece Material:

Alloy Steel

Machining Objective:

Drill Ø5.0mm tap hole & chamfer.

Description:

Cougar was approached to improve an existing drill design that would improve overall tool life during the holemaking process. We are always willing to compete, and this was no exception.

Our Solution/Results:

Cougar designed & produced a drill using proprietary drill point and post-processing techniques to provide a superior drill that achieved the customer goal. The result was a tool that increased tool life by 239%, on average, a massive savings. This was an expected success, but we are proud of our operators for knocking this out of the park. Truly a home run!